Cutting the box sections

As stated in the description I used 20x20x2 stainless steel box sections.

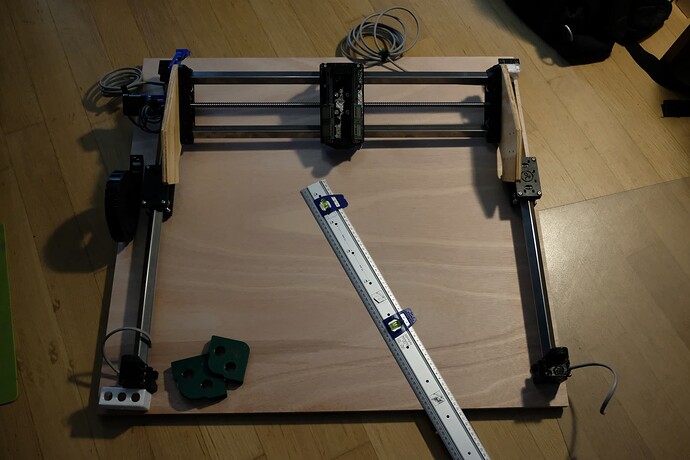

From the build area calculator, I needed 4 660mm pieces.

Warning:

In the following steps you’ll see me cutting 4 660mm pieces, but that’s a “scalable” measure, and in most cases you’ll have 2 pieces of one length and 2 of another, having them the same size is only a particular case of my build. If you have two different sizes just work with two at a time instead of 4.

Parts needed:

box sections - I ordered a 2m long and a 1m long, so I had to cut 1 660mm piece from the 1m bar and 3 from the 2m one.

The long story of working with stainless steel begins:

The original project uses aluminum, but uses 360mm and 410mm pieces. I wanted a bigger build, so I scaled up, and so came the fear of aluminum flexing too much. I asked in the discord, someone I can’t remember said he had a bit of wobble on the x axis with aluminum on a bigger than standard build. After checking online stores selling both 20x20x2 alu and stainless steel, the difference was around 20 Euro shipping included. I concluded that when spending hundreds of euros on building a machine, realizing that it wobbles because I wanted to save 20 Euro was not a scenario I wanted to find myself on, so I ordered 20x20x2 stainless steel bars. And then started the long story of working with stainless steel!!

The first tip you should remember if you have a long bar to cut in pieces is that you shouldn’t measure all the cutting points, mark them, and then cut everything. Measure the length from the tip, mark, cut (better longer than shorter), measure, mark, cut…

Remember that cutting removes some length. I selected 660mm as with 660x3 I had 1980mm, so I had 20mm for the blade’s kerf and to cut a little longer and refine afterwards.

I started with a manual saw as I previously worked with aluminum profiles, and I thought it should be easier to get a good straight cut… But stainless steel is not aluminum, and that’s why I went with it: it’s very hard! So yes, I tried the manual way, and I recommend it for aluminum builds.

After an hour or so of sawing I realized that It was too hard to cut, so I got out my angle grinder, loaded a cutting disk and started cutting. I cut everything a couple mm longer than 660 to be able to refine the cuts and get everything the right length after.

After I cut everything a bit longer, I removed some imperfections from the edges with a “cleaning fleece for removing dust and paint”. Probably not the best disk for the job, but I just needed to have clean edges to use to align the pieces.

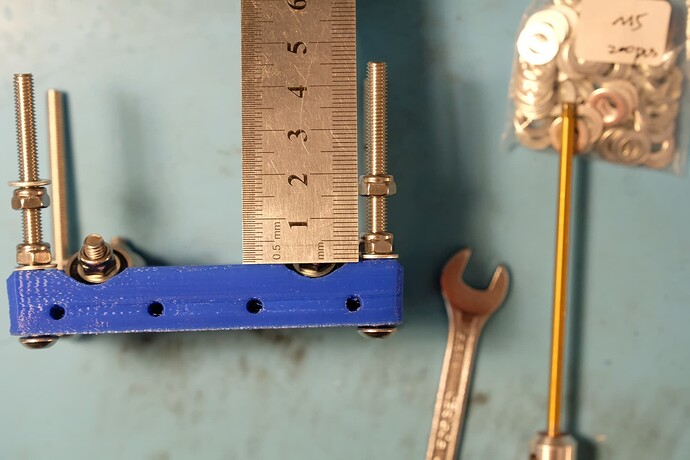

Then I aligned the box sections two by two using a square to get one end aligned.

Then I joined the four sections aligning them on the same side. (remember that you should not need to process the four sections together)

Next I clamped the four sections on the side I used to align and used an abrasive disk to get them all equal and square

I used the square to check for squareness

If you’re using aluminum it should be easy to do using a file or a sanding block.

you can use a marker to mark the edge

then you sand and look where the marker is removed and where not to Identify high and low spots.

When the first side is done you can measure again using the edge you just squared as a reference.

I used the square and a cutter to mark the steel with a precise, little, but durable mark all around the boxes to have a reference on all sides.

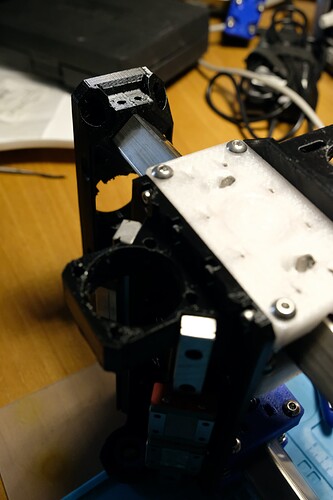

Then I clamped everything back vertically on the table (this time the other way up)

Then it’s only a matter of cutting, grinding, filing, whatever you need to get everything square and aligned with the cutter mark.

grinding everything perfectly square is pretty difficult with stainless steel, but in the end I got a good result, the length is almost perfectly what I needed.

In the end I smoothed the external edges with the “softer” disk and the inside ones with a file.

Final notes

I put a lot of effort on getting the length just right, probably more than needed, but I enjoy the process of building, I like trying to do it right, and anyway I didn’t have all the other parts, so I had time before I could go on with the build.

You can get by with way less precision, as long as you check that the box mounts align to the same length, but that’s how I enjoyed doing it, so I told you my experience!

After all this process I thought that it would be good to smooth and polish a bit the surfaces to help the bearings, so I sanded everything up to 1200 grit… but that’s out of the requirements of a normal build, maybe it’s even overkill and not completely worth it, so I’ll not detail that process.